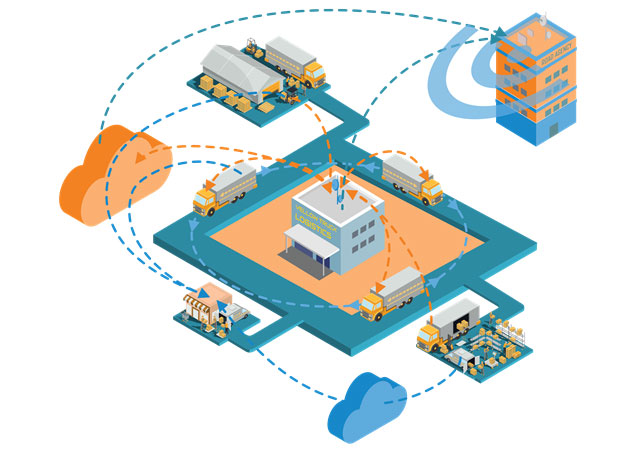

Qerp is a comprehensive resource planning and production management system that allows you to streamline all its stages and commercial components, financial accounting, as well as distribute tasks and control their implementation for employees of the enterprise.

The system is built on a modular principle, where each of the modules is individually configured for different types of production activities , which ensures transparency in the execution of all business processes with maximum accuracy.

The system is universal and can be easily applied to any type of production activity, taking into account the individual characteristics of each direction.

The main modules of the Qerp system :

- Production Module

- Commercial Module

- Warehouse Module

- Financial Module

- Design module

ITpass is a comprehensive resource planning and production management system that allows you to streamline all its stages and commercial components, financial accounting, as well as distribute tasks and control their implementation for employees of the enterprise.

The system is built on a modular principle, where each of the modules is individually configured for different types of production activities , which ensures transparency in the execution of all business processes with maximum accuracy.

The system is universal and can be easily applied to any type of production activity, taking into account the individual characteristics of each direction.

The main modules of the ITpass system :

- Production Module

- Commercial Module

- Warehouse Module

- Financial Module

- Design module